Production

Do you need specific series products or do you have a special machine insert? Are you missing a wear part with rare dimensions or do you need unusual and special products? Then VeRotool is the right partner for you.

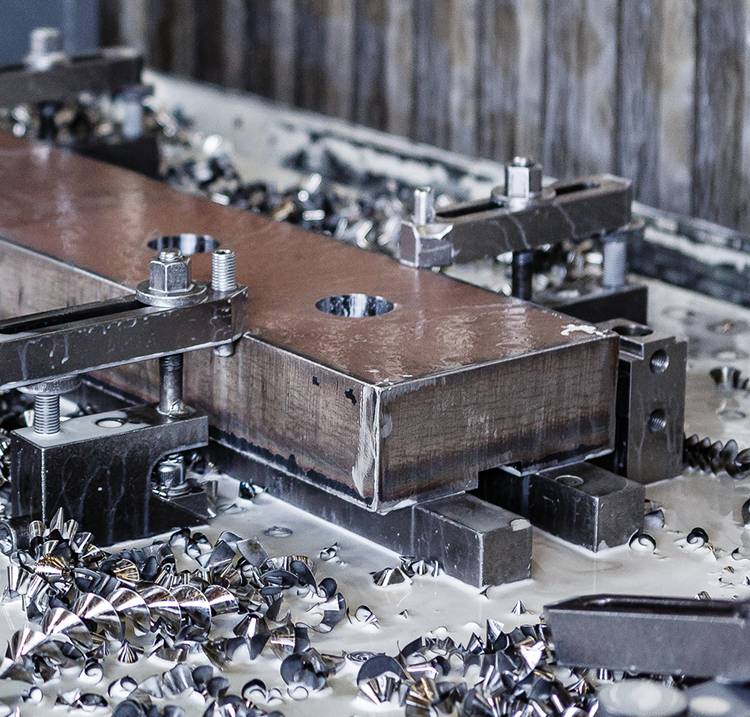

Our strength lies in the individual machining of highly wear-resistant steels. In our workshop, we manufacture a wide variety of wear parts in series or according to customer-specifications. Our know-how guarantees versatility and productivity – the materials used offer maximum wear protection and a long service life. We can take almost every individual request into account and attach great importance to quality.

Our services in detail:

- Production of bolt-on-edges and cutting edges for excavators and loaders (standard sizes and custom dimensions according to customer specifications

- Individual flame cutting and sheet metal processing in oxyfuel and plasma flame cutting processes (cuts from HARDOX sheets according to sketches, templates or digital files. Material in 400 – 550 HB and material thickness: 4 mm – 120 mm)

- Machining on our CNC-controlled machining centers (milling, drilling, countersinking, special countersinking for plow bolts and nip bolts as well as recesses, grooves and threaded holes)

- Bevelling/edging work

- Production of highly wear-resistant lining plates for hard crushers

- Fabrication of new screen plates for heavy-duty application

- Production of gravel blades for gravel washers

- Wear-resistant linings for gravel extraction and processing

- Custom-made-products according to customer specifications (e.g. hammer housing, heavy-duty bearing blocks and much more)