Wear parts for gravel washing plants

In the manufacture of wear parts for gravel extraction, materials must always be used that can withstand the highest wear stresses and thus guarantee a long service life of the products. Every retrofit of a plant is associated with enormous costs. The longevity of the products provides competitive advantages and protects the budget of the operating companies.

Our products in this segment are manufactured and supplied from steel sheets up to 550HB (mainly HARDOX) or from Ni-Hard casting.

In our workshop you can also have the most suitable products for your plants custom made - see also Customized products.

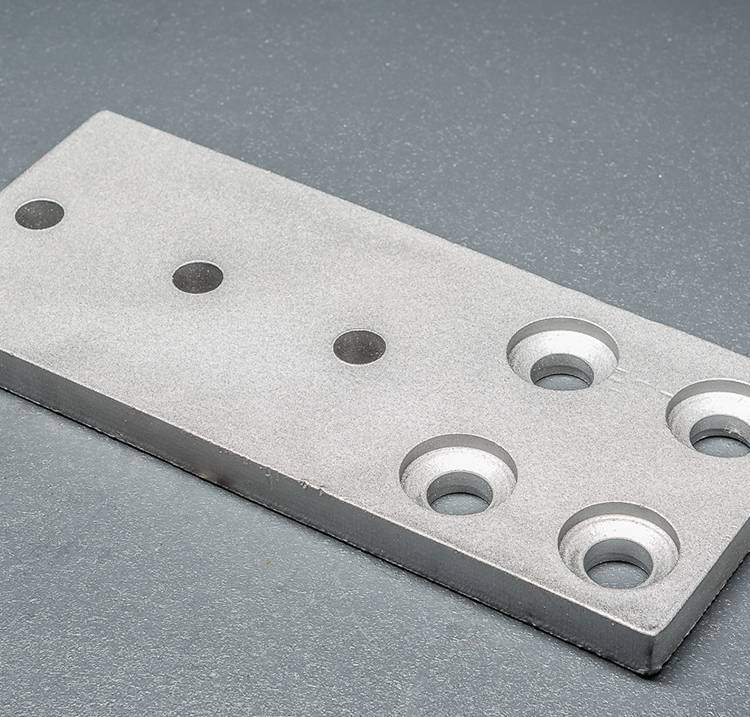

Products made of Steel sheets

As a certified HARDOX Wearparts Partner, we in the VeRotool workshop primarily use the particularly robust and resistant HARDOX wear plates from SSAB in this segment.

According to drawings or samples, we manufacture a wide variety of wear parts for all brands at the customer's request .

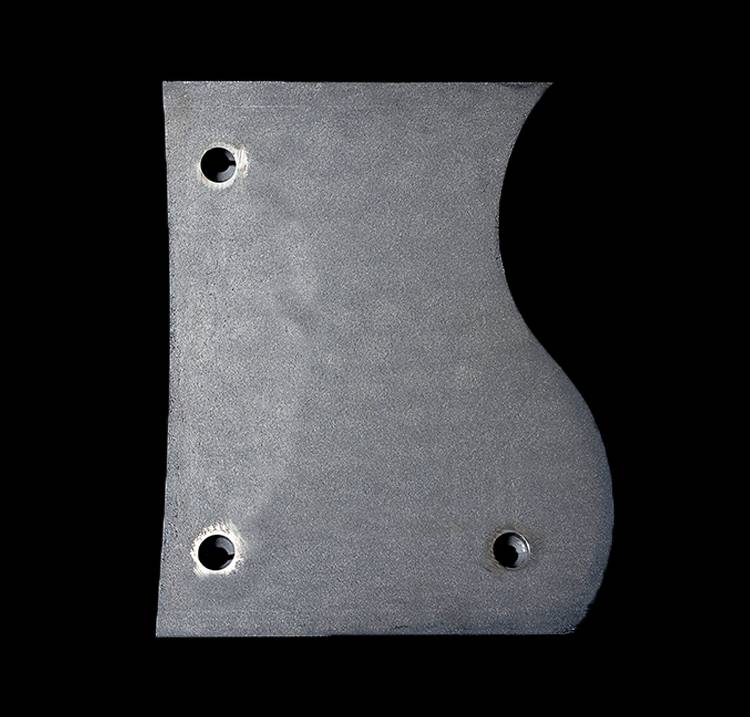

Ni-Hard cast products

Our cast products come from Europe and are very popular with our customers. The cast iron articles offer particularly high wear resistance and - compared to products made of sheet steel - an increase in service life.

Thanks to our long-standing cooperation with the Swedish foundry Bruzaholms Bruk (BZH), we can offer lots of products made of BZ95 material (the so-called "Swedish steel"). This material is a bit more expensive than steel sheets, but the durability of this material makes it quickly worthwhile to purchase.

We have had similarly good experiences with our products from another European foundry, such as clay grinders. We have been offering these for about three years and have gained many satisfied customers as a result.

We manufacture and supply the following products:

- Linings for material guides

- Gravel blades

- Blade brackets

- Shaft protectors

- Agitator parts

- Conveyor segments

- Clay grinders

- Auger blade segments

Other products upon request.